PSA Oxygen Plant, Medical O2 Generator,Oxygen Concentrator

All You want to know about PSA Oxygen Generator

What is PSA Oxygen Plant?

PSA is the abbreviation for Pressure Swing Adsorption. PSA oxygen production plants use clean compressed air as raw material , and high quality zeolite molecular sieves as adsorbent to produce oxygen from air.

The compressed air is adsorbed under pressure and desorbed under reduced pressure in the adsorber. Due to the aerodynamic effect, the rate of diffusion of nitrogen in the micro-pores of the zeolite molecular sieve is much greater than that of oxygen, and the nitrogen is preferentially adsorbed by the zeolite molecular sieve and the oxygen is aggregated to form oxygen. Then by reducing the pressure to atmospheric pressure, the adsorbent desorbs the adsorbed nitrogen and other impurities to achieve regeneration. Generally two adsorption towers are set up in the system, one tower adsorbs and produces oxygen, the other tower desorbs and regenerates, and the PLC program controls the opening and closing of the pneumatic valve, so that the two towers alternately cycle, obtaining a high purity oxygen (93% ± 3%).

Hot Sale Types in the filed

With the outbreak of the COVID 19, we can customise medical oxygen generators according to customers’ needs, and also for industrial oxygen production. There are currently three best sell types.

Containerized PSA OXygen Generator

- Container: 10ft., 20ft. or 40ft

- The flow of oxygen:1-200 Nm3/h (20℃, 101.325KPA)

- The purity of oxygen: 93 ±3%

- Outlet pressure: 0.05 -0.06MPA

- Dew point of the atmosphere: ≤ -40℃

- Intelligent control, high efficiency, energy saving, convenient

PSA Oxygen Generator Plant

- The flow of oxygen:1-200 Nm3/h (20℃, 101.325KPA)

- The purity of oxygen: 93 ±3%

- Outlet pressure: 0.05 -0.06MPA

- Dew point of the atmosphere: ≤ -40℃

- Intelligent control, high efficiency, energy saving, convenient

Oxygen Concentrator

- The flow of oxygen:0-8L/min

- The purity of oxygen: ≥90%

- Outlet pressure: 04-0.08Mpa

- Power Consumption:650W

- Working Voltage:230V AC

- Noise Level:≤50dB

- Standard Function:Over Heat Alarm,Power Failure Alarm,Pressure Failure,Alarm,Timing Function,Working Hours Display

Containerized Psa Oxygen Plant type.VS Normal Type

Containerized oxygen plant

- No installing

- No commissioning

- No equipment room required

- Shipping no containers to order

- no need packaging

Normal Type PSA Oxygen Plant

- Need installing

- Need commissioning

- Need equipment room required

- Shipping order containers

- Fumigation-free wooden boxes are available for $110/cubic meter for sea freight.

Estimated PSA Oxygen Plant Cost

Minsheng Group produces high-quality PSA oxygen plant, and PSA nitrogen plant, to meet industrial oxygen, nitrogen, and medical oxygen requirements.

Your investment PSA oxygen generator price is inculding the price of the equipment and shipping cost.

The cost of investing in an oxygen generator is based on the amount of oxygen produced, accessories and whether it is containerised or not, generally a containerised oxygen generator is slightly more expensive than normal type, but does not have plant cost.

The model of the oxygen generator is determined by how many cubic metres of oxygen are required per hour and the height of the poster.

Common sizes range from 5m³-200m³. Prices range from $20,634.92-$195,238.10. For the detailed PSA Oxygen generator price, please click

6 tips for getting PSA oxygen generator price and model. get specific specifications you need and reference prices.

Containerized Psa Oxygen Plant cost, according to normal model add container cost, 20ft add $4687, 40ft add $8593

- Sipping Fee to Afria one container 3000USD

- Shipping Fee to Philippines, Vietnam, Myanmar, Thailand, Malaysia, Brunei, Singapore, Indonesia, Cambodia ect 2000USD

- Shipping Fee to Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Lebanon, Oman, Palestine, Tunisia and other Middle East countries 3000USD

- Shipping Fee to Ecuador, Colombia, Venezuela, Peru, Brazil, Chile, Uruguay, Paraguay, Argentina, Bolivia, Guyana, Suriname and other South American countries 7000USD

Our Internal Technical Data

To make it easier for you to understand. We have carefully prepared all the information about PSA oxygen generators. It will be very helpful for you to purchase PSA oxygen and nitrogen generators.

Detailed list of oxygen concentrator accessories

This list contains detailed descriptions of the accessories for each model

oxygen generator operationg manual

This list contains detailed descriptions of the accessories for each model

how to Power on and off operation process

Describe in detail how to operate the machine

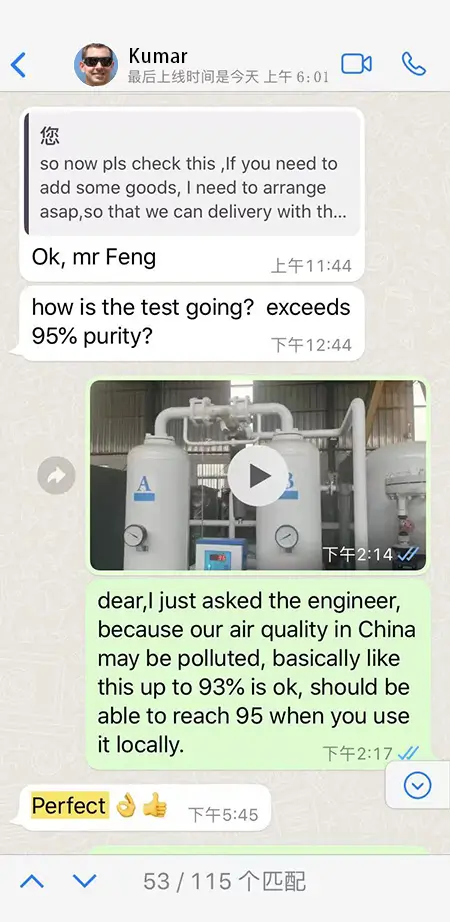

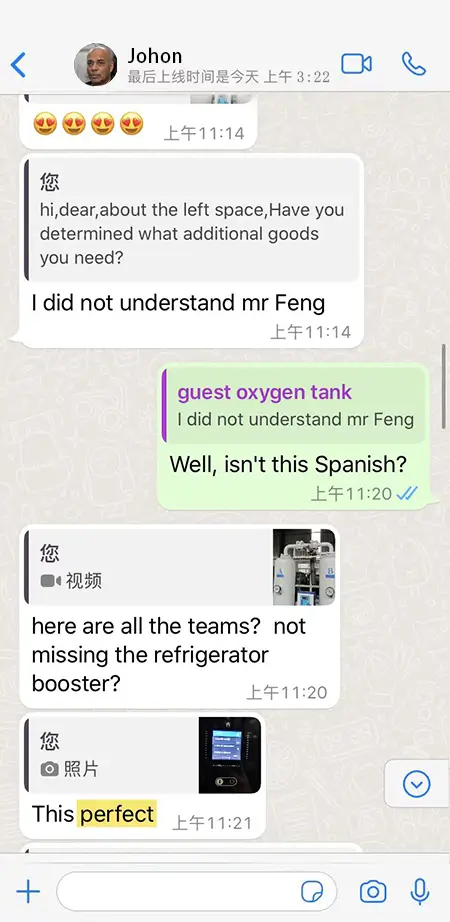

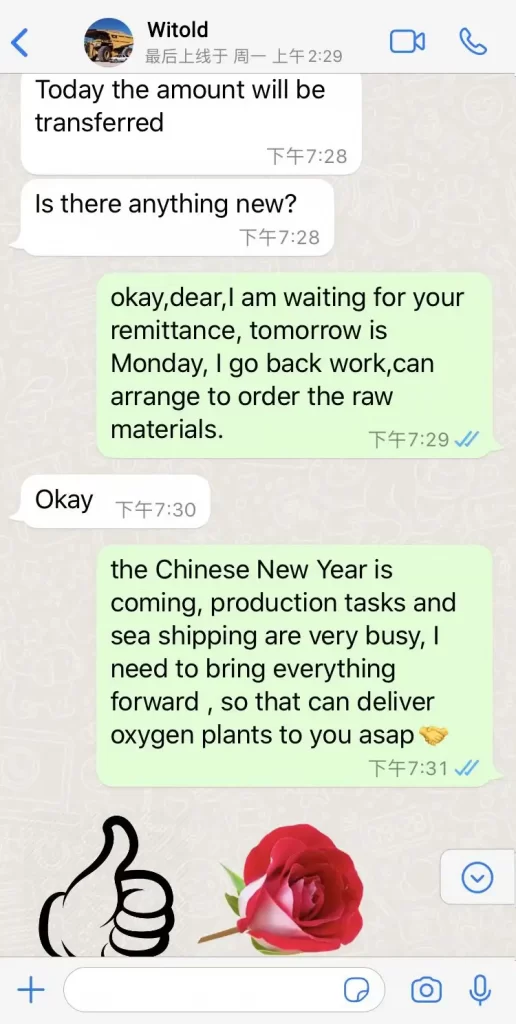

What My Clients Says

As a reliable PSA oxygen generator manufacturer, Our machines are popular with our customers

WHATSAPP TESTIMONIALS

Frequently Asked Questions

Most frequent questions and answers

1.The PSA oxgyen plant normally how many hours maximum it can work in a daya) 8 hours b) 12 hours c) 15 hours d) 24 hours,we want to know what the maximum working capacity per day, so as not to have a problem with the plant. Oxygen is scarce in our country, it is for this reason that we want to make it work 24 hours

According to your actual need for oxygen, the oxygen plant can work continuously for 24 hours,or 15 hours,or other.

2. Do you have an instruction plan for the installation of the oxygen plant?

I have given you “50m3 oxygen plant video ”, “how to start video”, “pipeline connection of booster video”. You just need to place each module according to the video I provided to you and then match each label according to the label I posted, then screw it on.

For example, as shown in the following figure, connect the two nozzles marked with the same number“2” with bolts.

After the connection,Follow the boot sequence as directed in the“how to start” video instruction, then plug in the power supply ,the plant can be used.

3.we need the schedule for the maintenance of each component.

1. The compressor works with a special type of oil, specify if it is mineral oil, we have the brands Shell, Mobil, Destron etc.Regarding the brand of engine oil, you can consult your local Atlas dealer. Our Atlas supplier’s recommendation is to use super synthetic lubricants, and there is no specific brand.

2. How many hours of work do we have to change the air filters of each component.

Depending on how long the plant has actually been running, combined with the spare parts replacement cycle given below, you can know when to replace parts and components

air compressor part

| Name | |

|---|---|

| 2000 hours maintenance | Filter maintenance kit |

| 4000hours maintenance | Filter maintenance kit |

| Oil separation | |

| 6000hours maintenance | Filter maintenance kit |

Oxygen generator part

| C class filter | Replace it every 6000hours , and regularly remove it for cleaning and blowing |

|---|---|

| T class filter | |

| A class filter | |

| H class filter | |

| Sterilization filter element | |

| Automatic drain | change it when it is broken |

booster part

| No | Name | Model | Quantity | Maintenance time | |

|---|---|---|---|---|---|

| 1 | Front guide ring | 120*4*40 | 4 | Piece | 4000hours |

| 2.1-class consumables | Piston ring | 130 | 8 | Piece | |

| Guide ring | 130*4*20 | 2 | Piece | ||

| Intake combination valve | AQBL14-41-00Y | 1 | Set | 6000 hour | |

| Exhaust combination valve | AQBL14-51-00Y | 1 | Set | ||

| 3. 2-class consumables | 80 double acting piston ring | 80 Piston ring | 4 | Piece | 3500hour |

| Guide ring | 80*3.2*20 | 2 | Piece | ||

| Intake combination valve | AQBL14-41-00Y | 1 | Set | 6000hour | |

| Exhaust combination valve | AQBL14-51-00Y | 1 | Set | ||

| 4. 3-class consumables | 45 rod piston ring | 5 | Piece | 2500hour | |

| 45 rod guide ring | 45*41*15 DX | 2 | Piece | ||

| Intake valve disc | Class 3 | 1 | Piece | Each year | |

| Exhaust valve disc | Class 3 | 1 | Piece | ||

| 5. 4-stage piston assembly | piston | 26 made self | 1 | Piece | 1500-2000hour |

| Piston ring | 26 Spiral ring | 7 | Piece | ||

| Piston O-ring | 14*3.55 Fluorine rubber | 14 | Piece | ||

| Guide ring | 26 made self | 1 | Piece | ||

| Throttling ring | 26 made self | 1 | Piece | ||

| Valve | SF6 | 4 | Piece | Each year | |

| 6. Stuffing box | Stuffed piston ring | Class 1 45 | 10 | Piece | 2000-2500hour |

| Stuffed piston ring | Class 2 45 | 10 | Piece | ||

| 7 | Lubricating grease | Antioxidant grease | 60 | g | Every two years |