PSA Nitrogen Generator

All You want to know about PSA nitrogen generator

what is psa nitrogen generator ?

Similar with the principle of PSA oxygen generator, the nitrogen generator uses high quality carbon molecular sieve as adsorbent and adopts the principle of variable pressure adsorption (PSA) to separate air and produce 95%-99.99% high purity nitrogen gas.

Nitrogen production capacity: 3Nm3/h – 500Nm3/h

Two Type of PSA n2 generator For Choose

Portable PSA nitrogen generator

Automatic operation of the equipment, efficient use of molecular sieve, unique airflow distributor, qualified nitrogen can be provided within 30 minutes, automatic discharge, no manual labor required.

- Nitrogen purity: 99%-99.99%

- Nitrogen flow: 3m³/h-20m³/h

- Nitrogen pressure: ≤0.65mpa

- Application range: food preservation, food, as long as, industrial chemical, beverage beer, laboratory, metallurgy, electronics, injection molding

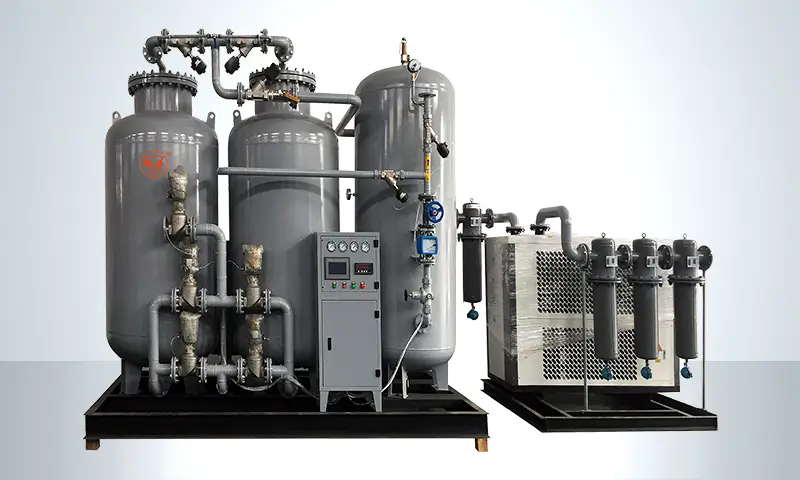

Skid-mounted Type PSA nitrogen generator

PLC fully automatic opening and stopping, automatic stopping when the pressure rises to 0.75Mpa, automatic operation when the pressure drops to 0.6Mpa, automatic emptying of unqualified nitrogen.

- Nitrogen purity: 99%-99.99%

- Nitrogen flow: 50Nm³/h-1000m³/h

- Nitrogen pressure: ≤0.65mpa

- Application range: food preservation, food, as long as, industrial chemical, beverage beer, laboratory, metallurgy, electronics, injection molding

Containerized PSA Nitrogen Generator

The container type nitrogen generator is installed in a box or container, which can be moved according to the demand in the process of use, with easy to move, simple maintenance, saving investment, and can meet the demand of customers for mobile gas.

- Nitrogen purity: 99%-99.99 (Customization is available)

- Nitrogen flow: 5Nm³/h-1000m³/h (Customization is available)

- Nitrogen pressure: 0.05~0.8Mpa (Customization is available

- Application range: food preservation, food, as long as, industrial chemical, beverage beer, laboratory, metallurgy, electronics, injection molding5

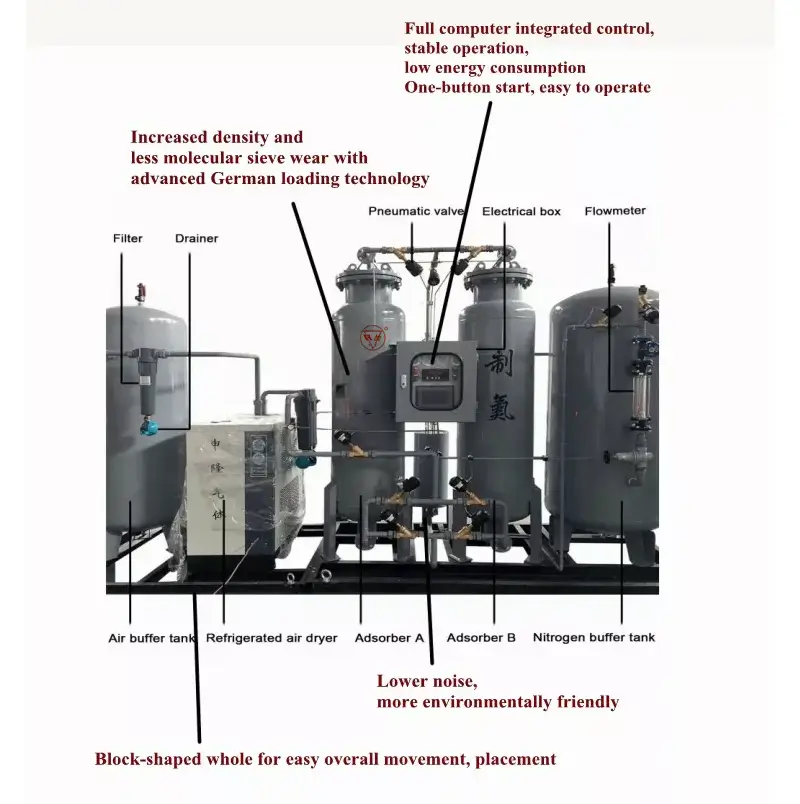

PSA nitrogen generator working principle

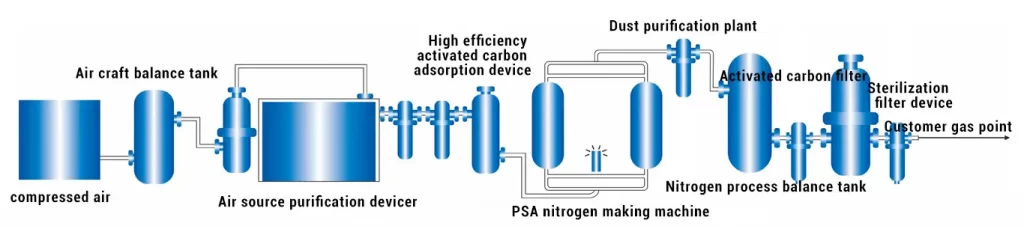

By describing in detail the components and processes of the PSA nitrogen generator system, you will learn that our equipment is of reliable quality, has a long service life, brings long-lasting economic benefits and avoids maintenance troubles caused by equipment failure.

The complete nitrogen production system consists of the following components.

Air compressor ➜ buffer tank ➜ compressed air purification unit ➜ air process tank ➜ oxygen and nitrogen separation unit ➜ oxygen process tank.

Advantages of our PSA Nitrogen generator

- The whole set of equipment adopts German Siemens PLC controller, which can realize automatic operation unattended and fault alarm prompt function.

- High degree of automation and fast gas production. Start-up and shut-down with a single button press, and gas production within 20 minutes of start-up.

- You never have to replace molecular sieves. The molecular sieve with high strength, high efficiency, and low energy consumption is selected, and the special molecular sieve protection measures, the adsorption structure of the spacer cylinder makes the molecular sieve bed always work under static, without any compression device, the molecular sieve never produces mechanical wear, which prolongs the service life of carbon molecular sieve

- The equipment has stable performance, easy operation, stable operation, high degree of automation, can realize unmanned operation, and low annual operating failure rate

The nitrogen production process of the nitrogen generator is to compress the air by the air compressor, enter the air storage tank, and then pass through the air treatment system refrigerated dryer to filter and remove the water, oil and dust in the compressed air, and turn the air into clean and stable. of compressed air

The clean air enters a pressure swing adsorption unit consisting of two adsorption towers equipped with carbon molecular sieves. The compressed air flows through the adsorption tower from bottom to top, oxygen molecules are adsorbed on the surface of the carbon molecular sieve, nitrogen flows out from the upper end of the adsorption tower, and enters the crude nitrogen buffer tank. After a period of time, the carbon molecular sieve in the adsorption tower is saturated with oxygen adsorbed. The two adsorption towers are alternately used for adsorption and regeneration to ensure the continuous output of nitrogen.

Estimated PSA Nitrogen Generator Price

Minsheng Group produce high quality PSA oxygen plant, PSA nitrogen plant, to meet industrial oxygen, nitrogen and medical oxygen requirements.

Your investment oxygen gerator costs are the price of the equipment and shippping cost.

The cost of investing in a nitrogen plant system is mainly the equipment price and shipping fee, Different prices for different equipment models.

How to choose PSA nitrogen generator.

- nitrogen purity (95-98% purity is mainly used for industrial blowing with, coal mine protective gas, magnesium powder processing and other fields. (General food packaging preservation 99.5-99.9%, milk powder coffee packaging preservation 99.99%, laser cutting 99.99%, high purity nitrogen 99.999% mainly for laboratory).

- the voltage frequency.

- Altitude

- Fourth, the use of scenarios: nitrogen machine output nitrogen is generally directly connected to the downstream equipment nitrogen access port (such as food packaging machines), nitrogen generally do not need a booster, part of the need to use booster occasions: for fire extinguishers need to pressurize the nitrogen into the fire extinguisher cylinder, laser cutting may also be used to pressurize the booster to facilitate the laser cutting of thick plates

Box type n2 generator, add $1093 according to different model

Containerized Psa N2 generator price, according to normal model add container cost, 20ft add $4687, 40ft add $8593

Shipping Fee

- Sipping Fee to Afria one container 3000USD

- Shipping Fee to Philippines, Vietnam, Myanmar, Thailand, Malaysia, Brunei, Singapore, Indonesia, Cambodia ect 2000USD

- Shipping Fee to Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Lebanon, Oman, Palestine, Tunisia and other Middle East countries 3000USD

- Shipping Fee to Ecuador, Colombia, Venezuela, Peru, Brazil, Chile, Uruguay, Paraguay, Argentina, Bolivia, Guyana, Suriname and other South American countries 7000USD

Application Case

Our machines are widely used in industries and fields such as heat treatment of non-ferrous and ferrous metals, chemical industry, rubber industry, pharmaceutical industry, food industry, metallurgical industry, electronics industry, glass industry, coal industry, aerospace technology support, petroleum industry, plastic industry, textile industry, etc.

N2 Generator For SMT welding

SMT electronic assembly industry, the use of nitrogen can effectively inhibit the oxidation of solder, avoid bridging, reduce welding defects

N2 generator for Food preservation

Applied to food packaging, food preservation, food storage, food drying and sterilization, nitrogen insurance is safe and environmentally friendly, isolates air, directly inhibits bacterial growth, extends warranty time, low cost and high economic efficiency.

N2 Generator For Medical

Mainly used in pharmaceutical packaging, pharmaceutical replacement gas, pharmaceutical transport atmosphere, etc.

N2 Generator For Chemical Industry

Create oxygen-free atmosphere in chemical processes to improve the safety of the production process, fluid transfer power source, etc.

For metallurgy, metalworking industry

Heat treatment industry applications Steel, iron, copper, aluminum products annealing, carbonization, high-temperature furnace protection, low-temperature assembly of metal parts and plasma cutting, etc.

N2 Generator For Microbiology Industry

The anaerobic environment fosters the growth of microorganisms that organically combine to produce proteins, nucleic acids and nitrogen-containing metabolites.

What My Clients Says

Our machines are popular with our customers

WHATSAPP TESTIMONIALS