How to select and verify reliable oxygen cylinder suppliers

Oxygen cylinders belong to high-pressure seamless gas cylinders. Because its pressure is higher than other (LPG Gas) cylinders. The danger is bigger, also more strict to the oxygen cylinder safety.

Everyone, who wants to grow your oxygen cylinder business and find a reliable supplier, Doesn’t know which one is your best choice? This blog will introduce you to how to audit and verify oxygen cylinder suppliers for your long-term cooperation.

Let’s get started.

when you want to select your oxygen cylinder suppliers you may check as follow tips:

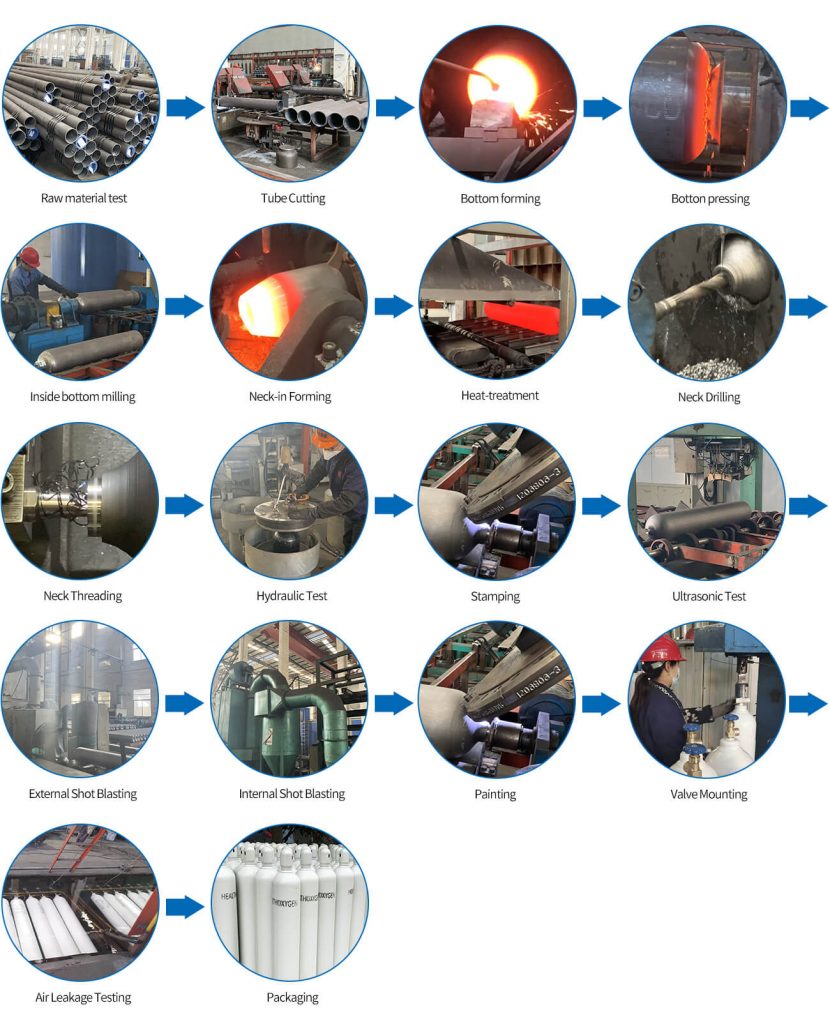

Step 1 Oxygen Cylinder Manufacturing Process

Formal production manufacturer needs to have a complete process flow,

Minsheng Group main processes of oxygen cylinders are :

Raw Material Test → Tube Cutting → Bottom Pressing → Inside Bottom Milling → Neck-in Forming → Heat-treatment → External Shot Blasting → Hardness Test → Neck Drilling → Neck Threading → Hydraulic Test → Stamping → Ultrasonic Test → External Shot Blasting(Internal Shot Blasting)→ Painting → Valve Mounting → Air Leakage Testing → Packaging

Step 2 Cost control is related to the final price

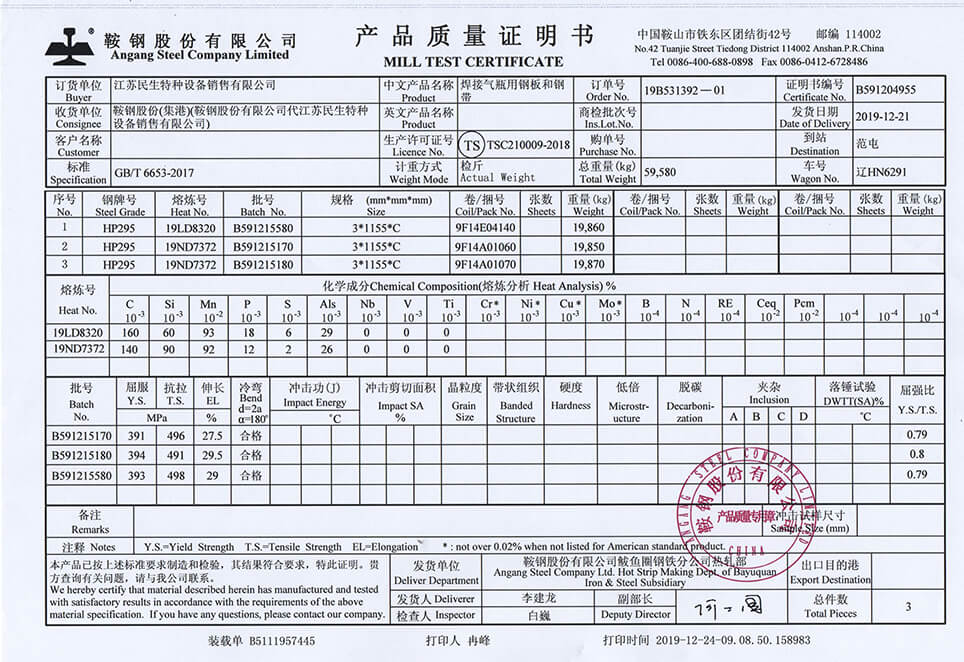

All buyers concern about the price, for the factory, can control the price mainly by controlling the cost, the process flow shown above only raw materials procurement can reduce production costs. But the reasonable selection of seamless steel tubes is the key to ensure the quality of the oxygen cylinder. Some factories will save costs to buy low-quality steel pipe, the surface looks like the buyers got a low price, in fact, caused losses.

Minsheng group directly purchases raw materials from the world’s top 500 suppliers Angang, Baosteel. The supplier provides the detailed chemical analysis report. Minsheng laboratory test chemical analysis of raw materials reinspection in accordance with national standards and ISO standards. Through drop weight test, hardness test, tensile test, bending test to further judge the plasticity and toughness of raw materials.

The main reason we can guarantee the price is:

Our factory orders large quantities of raw materials at rock-bottom prices

We are close to the raw material factory, so we can save the logistics expenses and short delivery

We have a long-term contract with the raw material factory. No major changes due to market fluctuations.

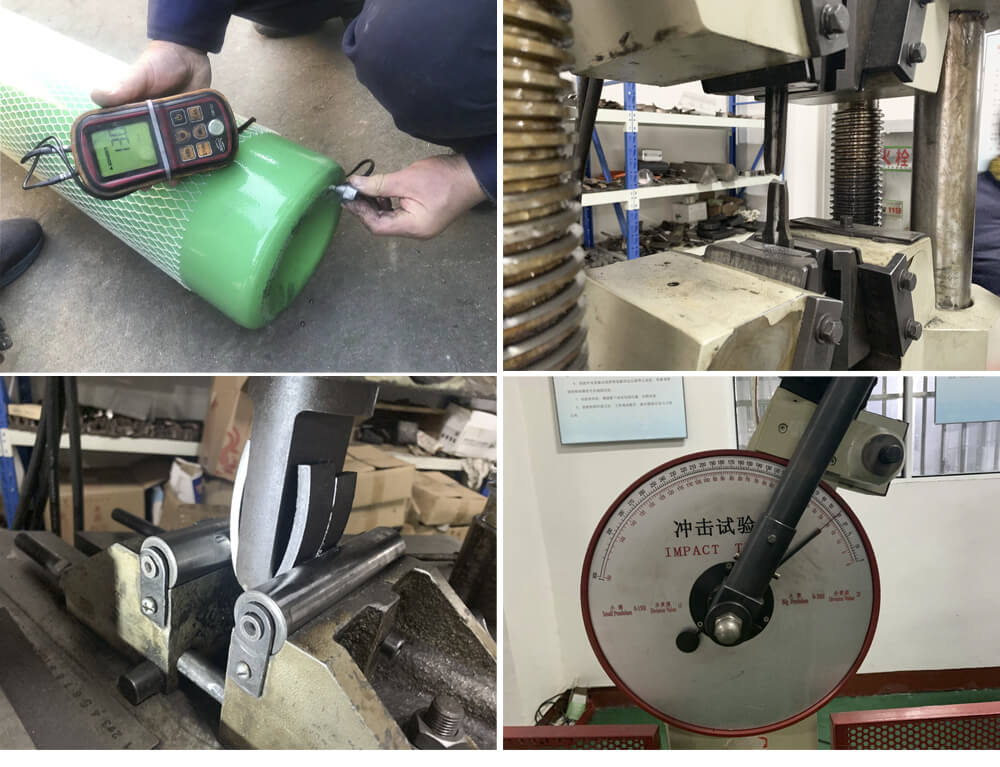

Step 3 Check their oxygen cylinder testing

The oxygen cylinder must have the following test items from raw materials to delivery.

- Raw material chemical composition analysis

- Raw material Mechanical performance test

- Semi-finished product Mechanical performance test

- Hardness checking

- Hydraulic test

- Blasting test

- Fatigue test

- Ultrasonic test

- Air Leakage test

After Heat Treatment, the oxygen cylinders are first inspected for appearance quality, and then hardness is tested one by one. tensile test, impact test, bending test, and blasting test are carried out according to the batch. It ensures the safety and reliability of the oxygen cylinder.

For the seamless gas cylinder, our company adopts 100% automatic ultrasonic testing, non-destructive testing is an effective way to ensure the quality of gas cylinders.

Before storage, the seamless gas cylinders should be made hydraulic pressure test and the key test procedure is air leakage testing

Hydrostatic test is the most commonly used testing method for gas cylinders. Through Hydrostatic test, on the one hand, test the strength of gas cylinders ; on the other hand, measure the residual deformation rate of gas cylinders to check the heat treatment condition.

For the inspection of the valve part, the air leakage test method is mainly used to ensure the safe operation of the cylinder.

Step 4 Check their key production equipment

A factory in addition to professional testing equipment, but also the need for professional production equipment.

The cutting pipe through the hot spinning process: bottom forming—— bottom pressing——inside bottom milling ——neck in

Hot spinning produced seamless gas cylinder has the advantages of uniform and smooth wall thickness transition, high surface smoothness, compact structure, and high production efficiency

Our Heat treatment equipment uses a continuous pusher tempering furnace, automatic temperature recording, high insulation accuracy. After many heat treatment process tests, we found that the appropriate heat treatment temperature is good, heat preservation time, the cooling rate can make the seamless gas cylinder obtain better plasticity and toughness.

The key process to determine the quality of seamless gas cylinders after forming

Heat treatment has a decisive effect on the quality of seamless gas cylinders. After the hot spinning drawing, the billet needs normalizing to meet the mechanical property requirement.

Our Heat treatment equipment uses a continuous pusher tempering furnace, automatic temperature recording, high insulation accuracy. After many heat treatment process tests, we found that the appropriate heat treatment temperature is good, heat preservation time,

the cooling rate can make the seamless gas cylinder obtain better plasticity and toughness.

Step 5 Third-party test

Minsheng has the most advanced production technology for produce seamless gas cylinder

Minsheng Manufacturers in seamless gas cylinders have advanced production technology to complete all testing from raw materials to the factory, but also

Commission Professional third-party testing organizations:

BV, Tuv, SGS, the United Kingdom LR, Norway DNV, etc., to test the finished products, issued an authoritative test report. To provide customers with safe and secure gas cylinders.