Trustfull Manufacturer Of Cryogenic Cylinders

What is a cryogenic cylinder?

Cryogenic dewar cylinder is a kind of gas cylinder with high vacuum and multi-layer insulation. The outer wall is wrapped with multi-layer insulation material, which has super heat insulation performance. At the same time, the interlayer is pumped into high vacuum to form an excellent heat insulation system. This keeps the media in the bottle cool and protects them from the ambient temperature outside. The inner tank is used to store cryogenic liquids. Commonly used for storing and transporting cryogenic liquids such as liquid nitrogen, liquid oxygen, liquid argon, liquefied carbon dioxide, liquefied nitrous oxide and liquefied natural gas.

Main Features:

1. High vacuum multilayer insulation to ensure low evaporation rate.

2. The volume of gas cylinders is generally between 80L and 500L

3. Widely used in gas liquefaction, storage and gas, chemical and food transportation industries.

4. Built-in carburetor automatically provides stable and continuous gas of 10Nm³/h

5.3 Year vacuum warranty service

6. Innovative visual level gauge

7. Enhanced side head support

8. The stainless steel support structure between the inner shells is durable;

9. Stainless steel neck tube can withstand accidental low-temperature bottle rollover;

10. Adsorption material can maintain vacuum for a long time;

11. With bladder bursting disc, double protection of bladder safety;

12. Equipped with shell release device to protect the safety of the shell

Main uses:

It is generally used in the following fields:

1. Medical liquid oxygen can be used as centralized gas supply equipment to make the gas more pure and healthy;

2. Can hold high purity industrial liquid oxygen, used for metal cutting, welding, heating and aerobic transportation, etc.;

3. Can contain liquid argon, used for argon arc welding and other argon protection occasions;

4. Can contain liquid nitrogen, used for high purity nitrogen protection or food, medicine, biology and superconductivity, such as minus 196℃ liquid nitrogen cooling carrier.

5. Can contain liquid carbon dioxide, used for welding gas protection, can also be used for food freezing or preservation.

6. Liquefied natural gas can be used for metal cutting, heating and other places where natural gas can be used

7. Nitrous oxide can be used for analgesia or anesthesia in hospitals

Types Of dewar cryogenic cylinder

Dewar Cryogenic Cylinders are generally manufactured in four types : vertical dewar 、 horizontal dewar、microbulk tank and cryogenic tank.

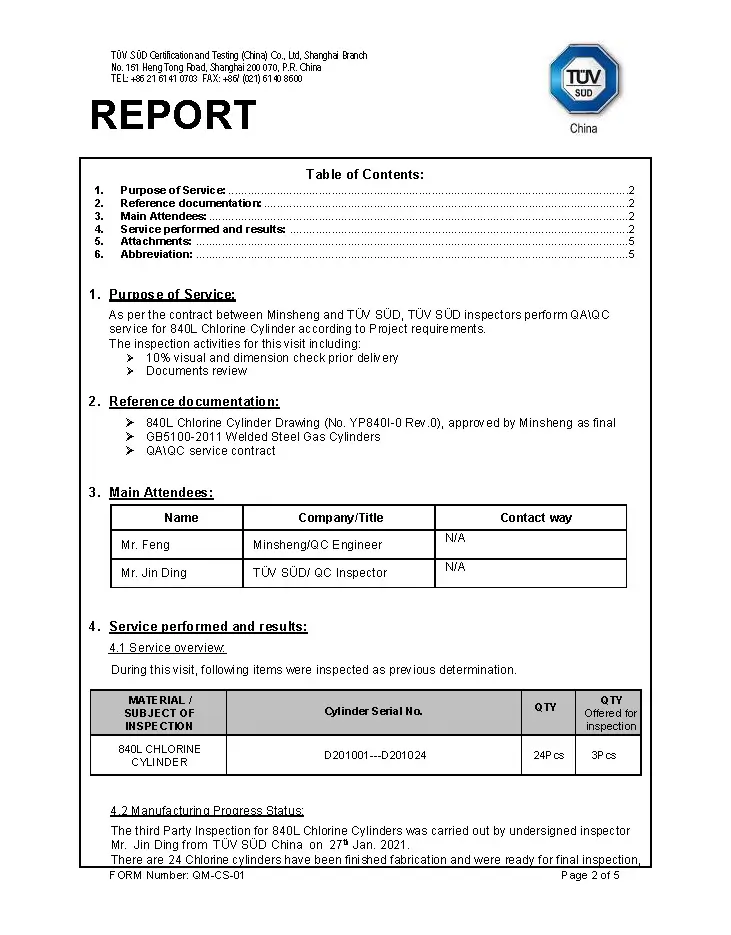

Vertical Dewar

1. Supercharging speed, vertical increase speed fast.

2. Vertical built-in carburetor, horizontal need to use external gasifier

3. Different structure forms.

4. Space ratio, simple structure, compact, easy to transport and installation

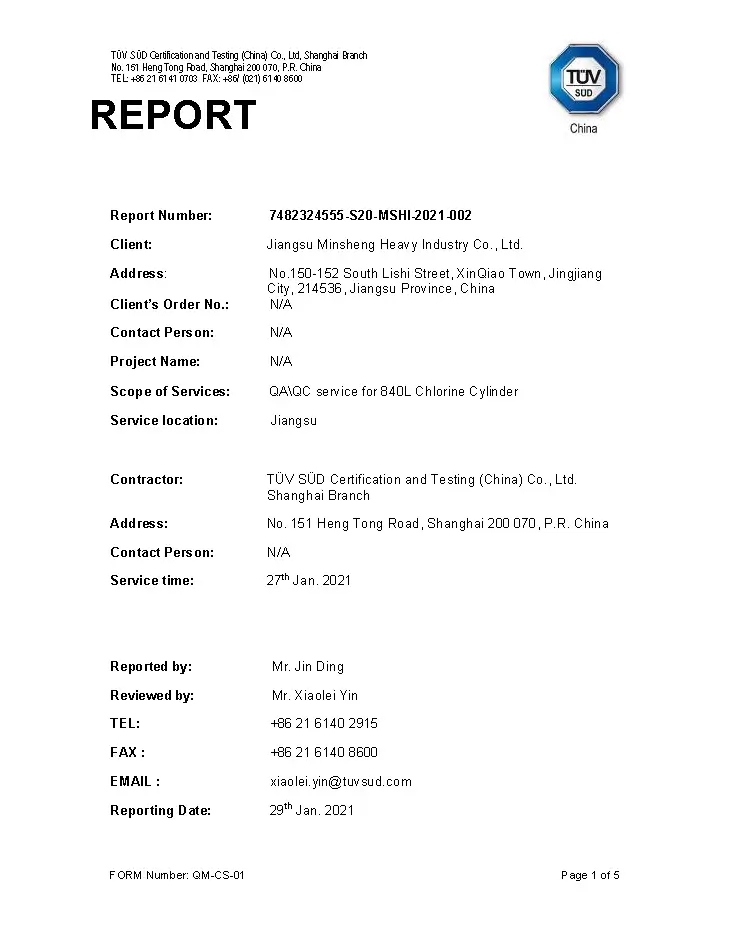

Horizontal Dewar

1. Supercharging speed, vertical increase speed fast.

2. Vertical built-in carburetor, horizontal need to use external gasifier

3. Different structure forms.

4. Space ratio, simple structure, compact, easy to transport and installation.

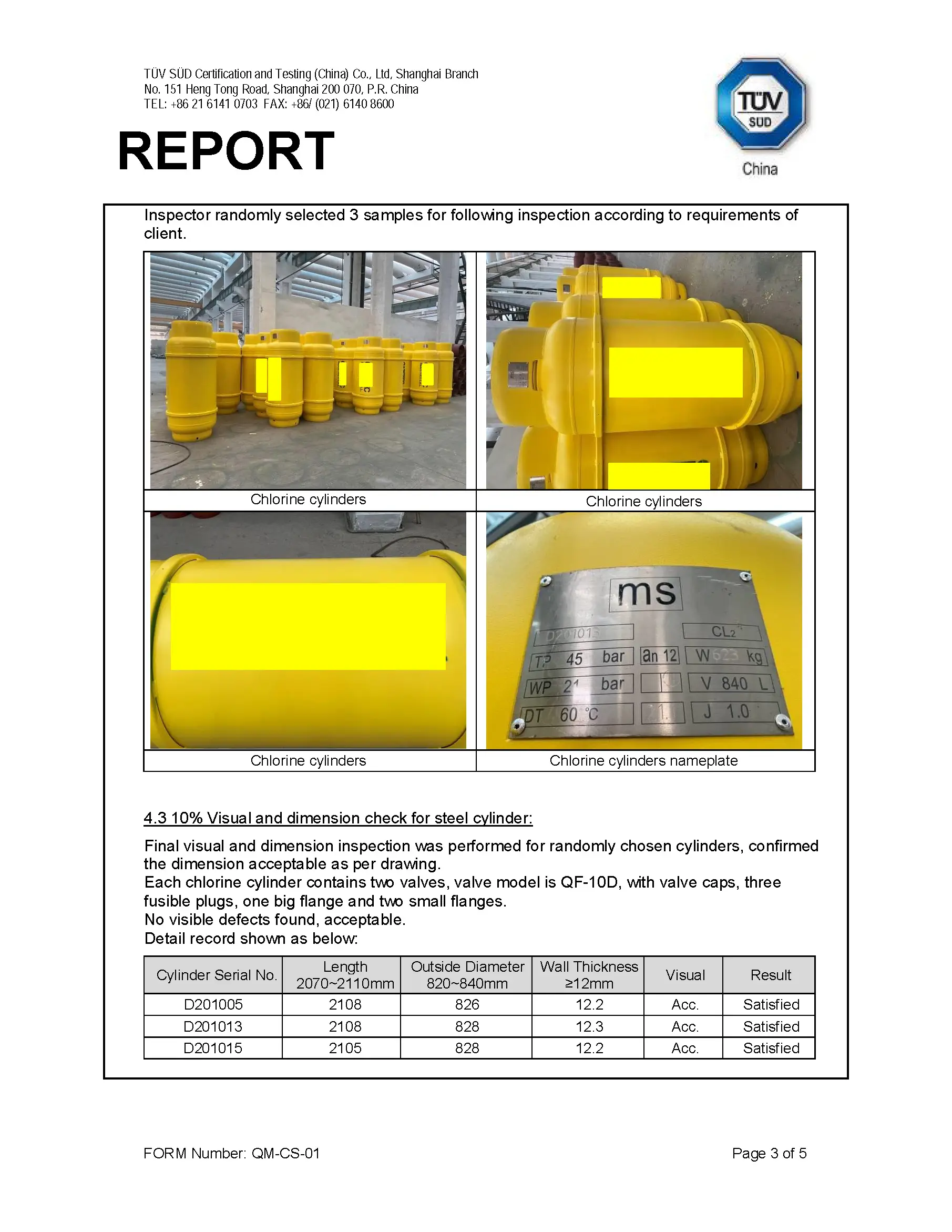

Microbulk Tank

1.Stainless steel shell, spiral polished,beautiful and corro-sion-resistant.

2.With bottom filling and top filling,fast filling speed and con-trollable pressure of storage tank

3.Forced pressurization mode,fast pressurization speed.

4.External vaporizer with high gas supply flow.

5.With gas outlet and liquid outlet for ease of use.

6.Double safety system,rupture disc+safety valve,to ensure the safety of the vessel.

7.Bottom pallet,convenient for forklift transport and installation.

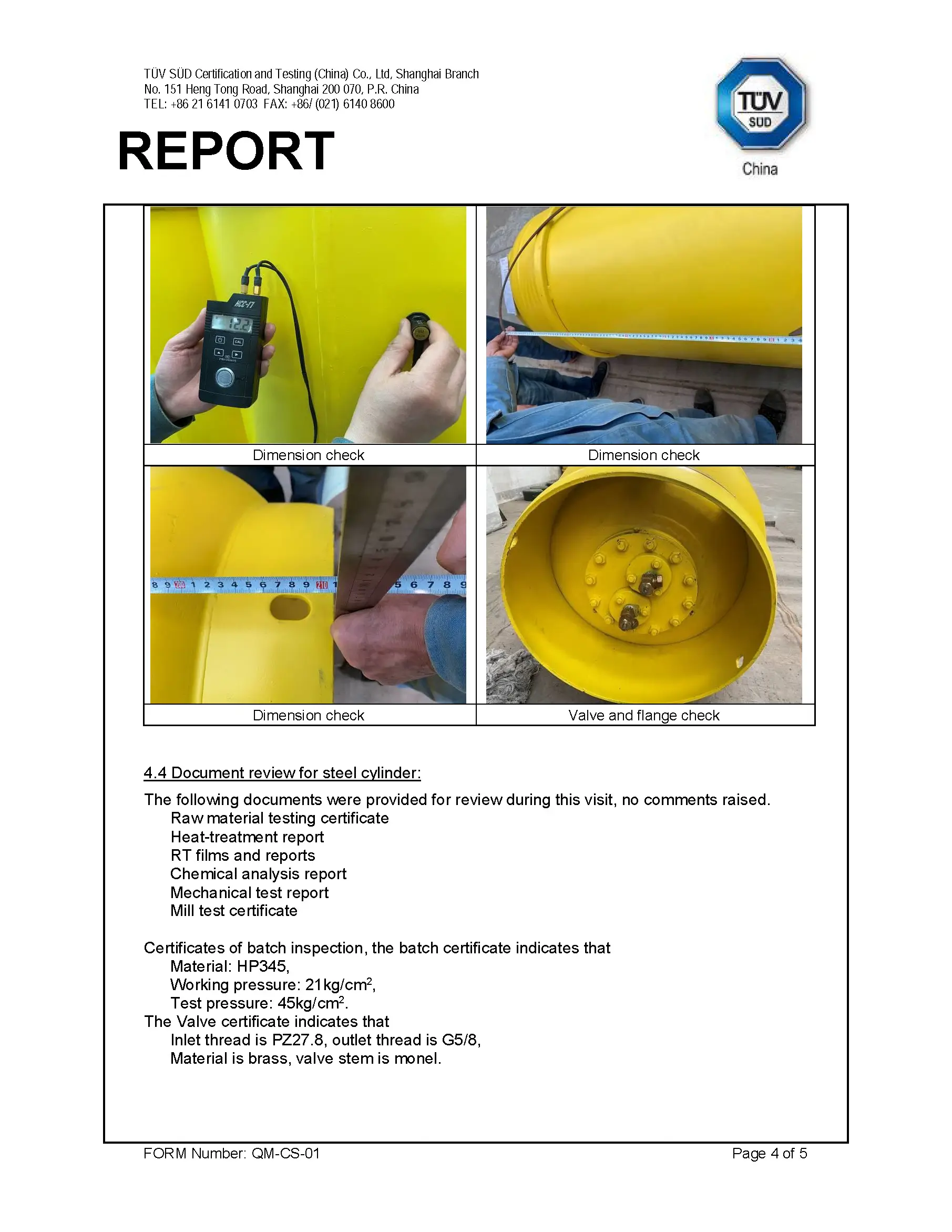

Cryogenic Tank

1.With bottom filling and top filling,fast filling speed and con-trollable pressure of storage tank

2.With gas outlet and liquid outlet for ease of use.

3.Bottom pallet,convenient for forklift transport and installation.

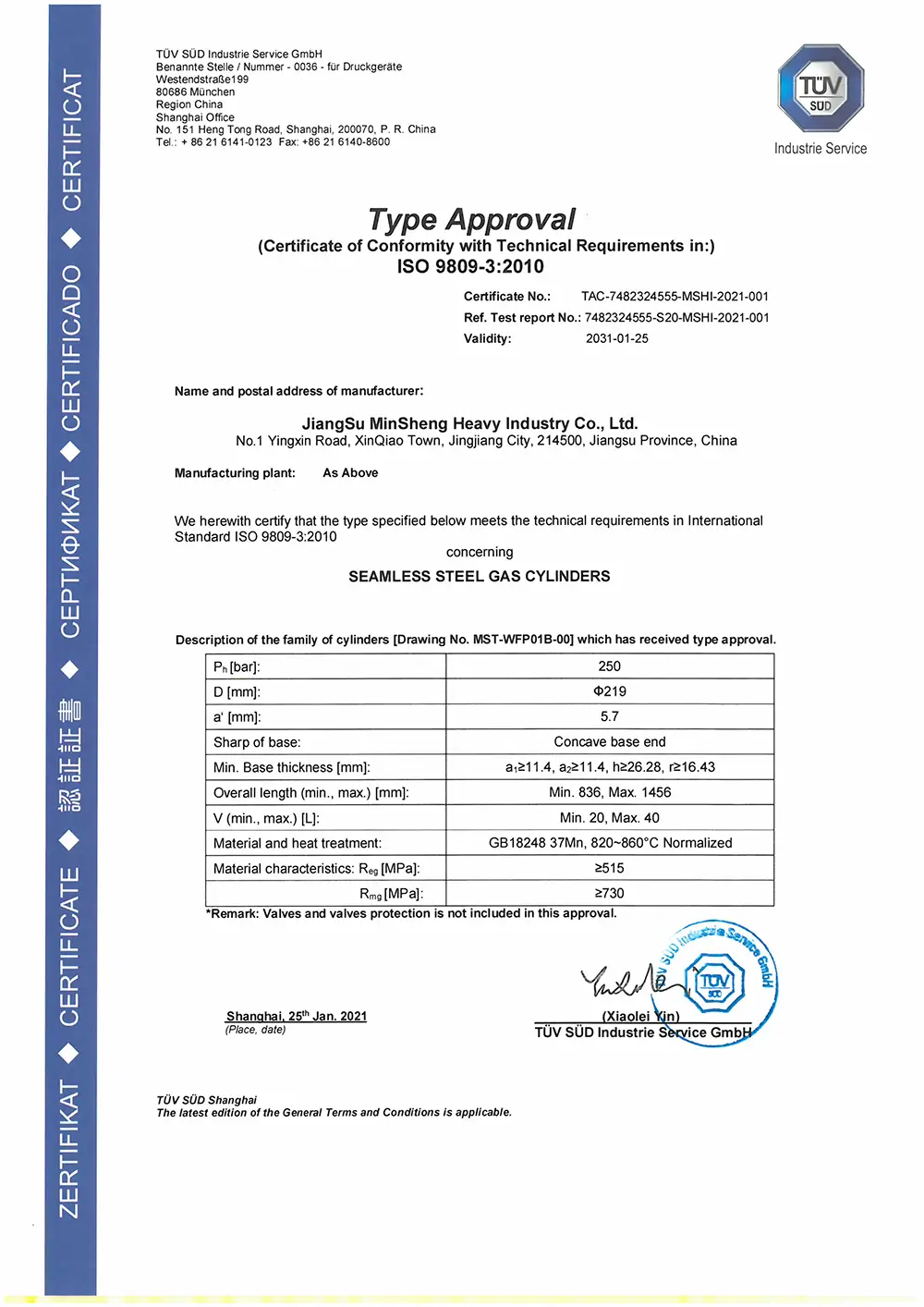

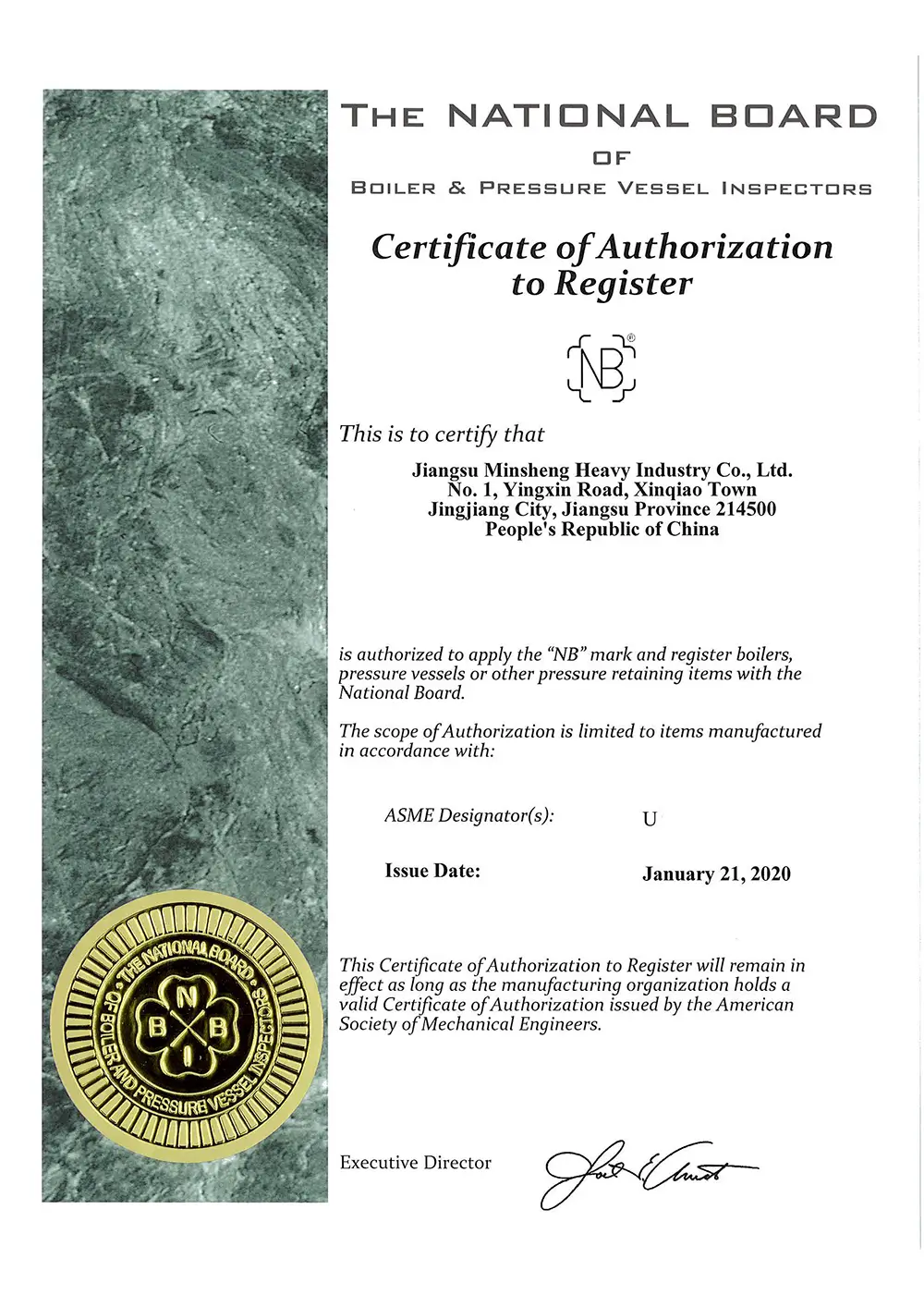

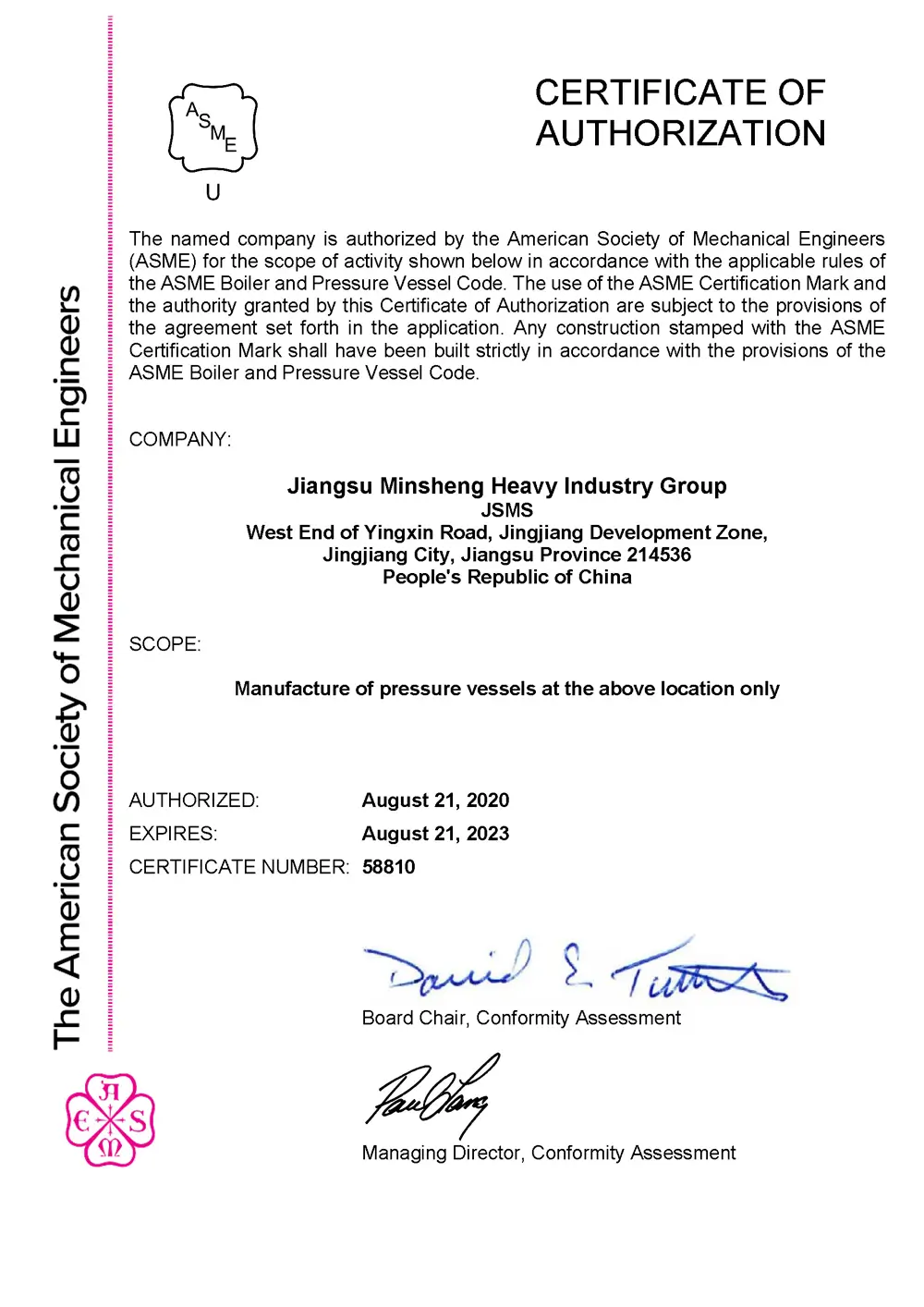

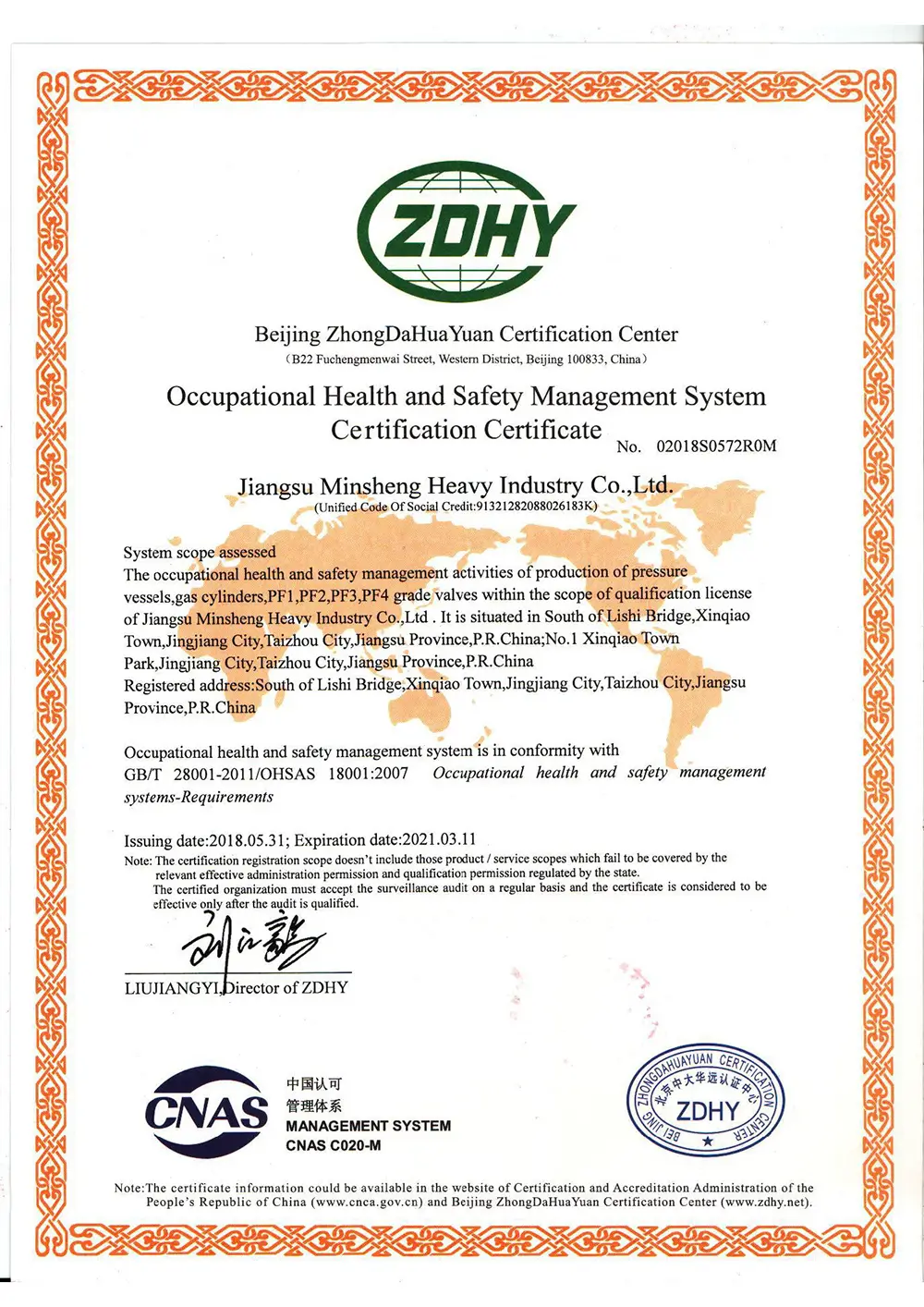

Note: Our factory are certified by American ASME , can produce on Asme standard and provide OEM service for you.

Dewar Cryogenic Cylinder Size Chart

The dewar can be made in various sizes, depending on the volume of material to be stored. ranging from 80 liters to 500 liters.

| Parameters of cryogenic cylinder for Mid-pressure DPL series | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Product Model | DPL450-150-1.37 | DPL450-175-1.37 | DPL450-195-1.37 | DPL450-210-1.37 | DPL450-232-1.37 | DPL710-410-1.38 | DPL710-450-1.38 | DPL710-480-1.38 | DPL710-499-1.38 |

| Dimension(O.D.XHeight) | Φ506*1395 | Φ506*1545 | Φ506*1670 | Φ506*1765 | Φ506*1905 | Φ766*1505 1100*860*1850 | Φ766*1607 1100*860*1950 | Φ766*1682 1100*860*2000 | Φ766*1730 1100*860*2065 |

| Empty Weight | 103 | 114 | 120 | 125 | 135 | 312(Including Frame) | 325(Including Frame) | 334(Including Frame) | 340(Including Frame) |

| Working Pressure | 1.37Mpa | 1.38Mpa | |||||||

| Nominal Service Pressure | 0.2~1.59Mpa | 0.2~1.59Mpa | |||||||

| Setting Pressure of Regulator | 0.86Mpa(Adjustment range from 0.52 to 1.21 Mpa) | 0.86Mpa(Adjustment range from 0.52 to 1.21 Mpa) | |||||||

| Safety Value Relief Pressure | Primary:1.59Mpa;Secondary:2.41Mpa(Only for LNG) | Primary:1.59Mpa;Secondary:2.41Mpa(Only for LNG) | |||||||

| Busting Pressure of Burst Disc | 2.6MPa(For the contents other than LNG) | 2.6MPa(For the contents other than LNG) | |||||||

| Nominal Volume | 150 | 175 | 195 | 210 | 232 | 410 | 450 | 480 | 500 |

| Effective Volume | 141 | 164 | 184 | 199 | 220 | 381 | 421 | 451 | 470 |

| Max.filling Weight(Oxygen) | 146 | 170 | 191 | 206 | 228 | 396 | 437 | 469 | 488 |

| Max.filling Weight(Nitrogen) | 102 | 119 | 133 | 144 | 160 | 277 | 306 | 328 | 342 |

| Max.filling Weight(Argon) | 179 | 208 | 234 | 253 | 279 | 484 | 535 | 575 | 597 |

| Max.filling Weight(LNG) | 58 | 68 | 76 | 82 | 91 | 158 | 175 | 188 | 195 |

| Gasflow Rate | LNG:7Nm³/hr;CO2:3Nm³/hr;Other content:9.2Nm³/hr(External vaporizer should be assembled if gas flow rate is not meet the requirement) | ||||||||

| NER(Nitrigen) | ≤2.47 | ≤2.10 | ≤2.05 | ≤1.98 | ≤1.97 | ≤1.83 | ≤1.80 | ≤1.74 | ≤1.70 |

| Liquid Level Gauge Type | Float(Default)or Capacitance level indicator(Optional) | Float(Default)or Capacitance level indicator(Optional) | |||||||

| Surface Treatment | Mechanical polishing | Mechanical polishing | |||||||

| Base Construction | Stainless steel-rubber base(Default)or Frame(Optional) | Frame with casters | |||||||

| Parameters of cryogenic cylinder for high-pressure DPL series | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Product Model | DPL450-80-2.3 | DPL450-100-2.3 | DPL450-120-2.3 | DPL450-140-2.3 | DPL450-175-2.3 | DPL450-195-2.3 | DPL450-210-2.3 | DPL710-410-2.3 | DPL710-450-2.3 | DPL710-499-2.3 |

| Dimension(O.D.XHeight) | Φ506*1025 | Φ506*1150 | Φ506*1275 | Φ506*1400 | Φ506*1545 | Φ506*1670 | Φ506*1765 | Φ766*1505 1100*860*1850 | Φ766*1607 1100*860*1950 | Φ766*1682 1100*860*2065 |

| Empty Weight | 88 | 97 | 112 | 124 | 135 | 146 | 151 | 360(Including Frame) | 385(Including Frame) | 401(Including Frame) |

| Working Pressure | 2.3Mpa | 2.3Mpa | ||||||||

| Nominal Service Pressure | 0.2~2.76Mpa | 0.2~2.76Mpa | ||||||||

| Setting Pressure of Regulator | 2.07Mpa(Adjustment range from 1.03 to 2.07 Mpa) | 2.07Mpa(Adjustment range from 1.03 to 2.07 Mpa) | ||||||||

| Safety Value Relief Pressure | 2.76Mpa | 2.76Mpa | ||||||||

| Busting Pressure of Burst Disc | 3.9Mpa | 3.9Mpa | ||||||||

| Nominal Volume | 80 | 100 | 120 | 140 | 175 | 195 | 210 | 410 | 450 | 499 |

| Effective Volume | 74 | 94 | 112 | 132 | 164 | 184 | 199 | 381 | 421 | 470 |

| Max.filling Weight(Oxygen) | 76 | 97 | 116 | 137 | 170 | 191 | 206 | 396 | 437 | 488 |

| Max.filling Weight(Nitrogen) | 53 | 68 | 81 | 96 | 119 | 133 | 144 | 277 | 306 | 342 |

| Max.filling Weight(Argon) | 94 | 119 | 142 | 167 | 208 | 234 | 253 | 484 | 535 | 597 |

| Max.filling Weight(LNG) | 78 | 99 | 118 | 139 | 173 | 195 | 211 | 404 | 446 | 498 |

| Max.filling Weight(LN2O) | 74 | 94 | 112 | 132 | 165 | 185 | 200 | 383 | 423 | 472 |

| Gasflow Rate | LNG:7Nm³/hr;CO2:3Nm³/hr;Other content:9.2Nm³/hr(External vaporizer should be assembled if gas flow rate is not meet the requirement) | |||||||||

| NER(Nitrigen) | ≤2.88 | ≤2.80 | ≤2.68 | ≤2.56 | ≤2.10 | ≤2.05 | ≤1.98 | ≤1.83 | ≤1.80 | ≤1.70 |

| Liquid Level Gauge Type | Float(Default)or Capacitance level indicator(Optional) | |||||||||

| Surface Treatment | Mechanical polishing | |||||||||

| Base Construction | Stainless steel-rubber base(Default)or Frame(Optional) | |||||||||

| Parameters of cryogenic cylinder for Superhigh-pressure DPL series | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Product Model | DPL450-80-2.88 | DPL450-100-2.88 | DPL450-120-2.88 | DPL450-140-2.88 | DPL450-175-2.88 | DPL450-195-2.88 | DPL450-210-2.88 | DPL710-410-3.17 | DPL710-450-3.17 | DPL710-499-3.17 |

| Dimension(O.D.XHeight) | Φ506*1025 | Φ506*1150 | Φ506*1275 | Φ506*1400 | Φ506*1545 | Φ506*1670 | Φ506*1765 | Φ766*1505 1100*860*1850 | Φ766*1607 1100*860*1950 | Φ766*1682 1100*860*2065 |

| Empty Weight | 96 | 108 | 120 | 131 | 150 | 162 | 170 | 427 | 449 | 458 |

| Working Pressure | 2.88Mpa | 3.17Mpa | ||||||||

| Nominal Service Pressure | 0.2~3.45Mpa | 0.2~3.45Mpa | ||||||||

| Setting Pressure of Regulator | 3.1Mpa(Adjustment range from 2.07 to 4.14 Mpa) | 3.1Mpa(Adjustment range from 2.07 to 4.14 Mpa) | ||||||||

| Safety Value Relief Pressure | 3.45Mpa | 3.45Mpa | ||||||||

| Busting Pressure of Burst Disc | 5.17Mpa | 5.6Mpa | ||||||||

| Nominal Volume | 80 | 100 | 120 | 140 | 175 | 195 | 210 | 410 | 450 | 499 |

| Effective Volume | 74 | 94 | 112 | 132 | 164 | 184 | 199 | 381 | 421 | 470 |

| Max.filling Weight(Oxygen) | 76 | 97 | 116 | 137 | 170 | 191 | 206 | 396 | 437 | 488 |

| Max.filling Weight(Nitrogen) | 53 | 68 | 81 | 96 | 119 | 133 | 144 | 277 | 306 | 342 |

| Max.filling Weight(Argon) | 94 | 119 | 142 | 167 | 208 | 234 | 253 | 484 | 535 | 597 |

| Max.filling Weight(LNG) | 78 | 99 | 118 | 139 | 173 | 195 | 211 | 404 | 446 | 498 |

| Max.filling Weight(LN2O) | 74 | 94 | 112 | 132 | 165 | 185 | 200 | 383 | 423 | 472 |

| Gasflow Rate | LNG:7Nm³/hr;CO2:3Nm³/hr;Other content:9.2Nm³/hr(External vaporizer should be assembled if gas flow rate is not meet the requirement) | |||||||||

| NER(Nitrigen) | ≤2.88 | ≤2.80 | ≤2.68 | ≤2.56 | ≤2.10 | ≤2.05 | ≤1.98 | ≤1.83 | ≤1.80 | ≤1.70 |

| Liquid Level Gauge Type | Float(Default)or Capacitance level indicator(Optional) | |||||||||

| Surface Treatment | Mechanical polishing | |||||||||

| Base Construction | Stainless steel-rubber base(Default)or Frame(Optional) | Frame with casters | ||||||||

| Table 5-4 Product Parameters ofDPWSeries Cryogenic Cylinders | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Product Model | DPW650-410-1.59 | DPW650-480-1.59 | DPW650-499-1.59 | DPW650-410-2.5 | DPW650-480-2.5 | DPW650-499-2.5 | DPW650-410-3.45 | DPW650-480-3.45 | DPW650-499-3.45 |

| Dimension(L*W*H) | 1850*770*1020 | 2050*770*1020 | 2100*770*1020 | 1850*770*1020 | 2050*770*1020 | 2100*770*120 | 1850*770*1020 | 2050*770*1020 | 2100*770*1020 |

| Empty Weight | 301(Including Frame) | 327(Including Frame) | 335(Including Frame) | 350(Including Frame) | 381(Including Frame) | 391(Including Frame) | 387(Including Frame) | 426(Including Frame) | 433(Including Frame) |

| Working Pressure | 1.59Mpa | 2.5Mpa | 3.45Mpa | ||||||

| Nominal Service Pressure | 0.2~1.72Mpa | 0.2~2.76Mpa | 0.2~ | ||||||

| Setting Pressure of Regulator | 1.0Mpa(Adjustment range from 0.52 to 1.21Mpa) | 2.07Mpa(Adjustment range from 1.03 to 2.07Mpa) | 3.45Mpa(Adjustment range from 2.07 to 4.14Mpa) | ||||||

| Safety Value Relief Pressure | Primary:1.72Mpa;Secondary:2.41Mpa(Only for LNG) | 2.76Mpa | 4.0Mpa | ||||||

| Busting Pressure of Burst Disc | 2.6MPa(For the contents other than LNG) | 3.9Mpa | 5.6Mpa | ||||||

| Nominal Volume | 410 | 480 | 500 | 410 | 480 | 500 | 386 | 452 | 469 |

| Effective Volume | 386 | 452 | 469 | 386 | 452 | 469 | 386 | 452 | 469 |

| Max.filling Weight(Oxygen) | 401 | 470 | 487 | 401 | 470 | 487 | 401 | 470 | 487 |

| Max.filling Weight(Nitrogen) | 280 | 328 | 341 | 280 | 328 | 341 | 280 | 328 | 341 |

| Max.filling Weight(Argon) | 490 | 574 | 596 | 490 | 574 | 596 | 490 | 574 | 596 |

| Max.filling Weight(CO2) | / | / | / | 409 | 479 | 497 | 409 | 479 | 497 |

| Max.filling Weight(LN2O) | / | / | / | 388 | 454 | 471 | 388 | 454 | 471 |

| Max.filling Weight(LNG) | 160 | 188 | 195 | / | / | / | / | / | |

| Gasflow Rate | External vaporizer should be configured by customers according to the using requirement | ||||||||

| NER(Nitrigen) | ≤1.82 | ≤1.74 | ≤1.70 | ≤1.82 | ≤1.74 | ≤1.70 | ≤1.82 | ≤1.74 | ≤1.70 |

| Liquid Level Gauge Type | Capacitance level indicator | ||||||||

| Surface Treatment | Polishing | ||||||||

| Base Construction | Frame with casters | ||||||||

Benefits Of Dewar Cryogenic Cylinders:

Dewar cryogenic bottles have several advantages over traditional storage containers.

1. High loading rate: because the cryogenic liquid is stored in the cryogenic bottle, the amount of gas filled is much more than that of the ordinary gas bottle. The amount of gas filled in a 195L cryogenic bottle is equivalent to the amount of gas filled in 22 seamless 40L cylinders.

2. Long service life: low-temperature cylinders made of austenitic stainless steel, beautiful and rust-proof, can be used for a long time. Different from ordinary seamless cylinders, low-temperature cylinders can continue to be used after maintenance after leakage and other phenomena.

3. Good cleanliness: the cryogenic gas cylinder is made of stainless steel, clean and tidy. At the same time, the cryogenic liquid is stored in the bottle, with almost no other impurities, so as to ensure the high purity of the medium and the gas released is more pure and healthy.

4. High safety: the working pressure of low-temperature bottle is low, generally not more than 3.5mpa. At the same time, the low-temperature bottle is equipped with safety valve and explosion-proof plate, which can effectively prevent the occurrence of gas cylinder explosion and other accidents.

Dewar Cryogenic Cylinders Price

The price of dewar Cryogenic Cylinder is a very important factor when you are buying it. You should go for a cylinder that is not only affordable but also durable. Dewar Cryogenic Cylinder cost is determined by the size, material, and type of insulation. The most common materials used for Dewar Cylinders are stainless steel.